Staples and Stitching

Staples and Stitching

Presco stocks a wide range of staples and stitching wire for binding and fixing leaflets, brochures and documents. From brands like Rapid, Nagel, Stago and many more we have all these staple sizes available in stock to fit almost any machine. If you can’t see what you’re looking for, just get in touch and we’ll be able to help.

-

Etona Staples

From £3.87 Ex. VAT -

Heavy Duty Staple Gun – Stanley TR150HL

£32.14 Ex. VAT -

Insert Heads and Opto Cable for Rapid Staplers

From £69.00 Ex. VAT -

Nagel Staples

From £8.21 Ex. VAT -

Plockmatic Staples

From £13.75 Ex. VAT -

Rapid 106 E Stapler including 25,000 FREE staples

£599.00 Ex. VAT -

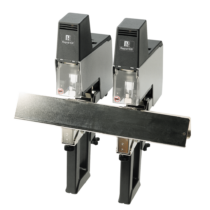

Rapid 106 Twin Head Stapler

£1,399.00 Ex. VAT -

Rapid 12/16 Long Arm Stapler

£83.40 Ex. VAT -

Rapid HD 210 Stapler

£125.08 Ex. VAT -

Rapid Staples

From £3.76 Ex. VAT - Sale!

Skrebba Staples

From £28.00 Ex. VAT -

Snail Cartridge Staples for Duplo, Rexel, Swingline, Plockmatic, Xerox, Kas

£20.98 Ex. VAT

How are staples and stitching wire used?

Staples and stitching wire are commonly used in print finishing to bind together multiple sheets of paper or other materials, creating booklets, pamphlets, and other multi-page documents. Here’s how staples and stitching wire are used in print finishing:

Staples:

- Saddle Stitching:

- Saddle stitching is a common binding method that uses staples. In this process, folded sheets are nested together and stapled along the spine. Saddle stitching is often used for booklets, magazines, and catalogues.

- Saddle Stitching Machines:

- Saddle stitching machines are employed in print finishing to automate the stapling process. These machines fold and staple the sheets simultaneously, increasing efficiency in high-volume production.

- Booklets and Brochures:

- Staples are commonly used to bind booklets and brochures, providing a simple and cost-effective binding method for smaller publications.

- Portable Staplers:

- For smaller-scale projects or manual binding, portable staplers can be used. These handheld devices are suitable for binding a limited number of sheets.

- Flat Stapling:

- Staples can be used for flat stapling, where sheets are stapled together along one edge without folding. This method is common for packets, reports, or presentations.

- Heavy-Duty Staplers:

- In industrial or commercial settings, heavy-duty staplers may be used to staple larger stacks of paper with greater efficiency.

Stitching Wire:

- Wire Stitching Machines:

- Wire stitching machines are designed for high-speed, automated binding using stitching wire. These machines can handle large volumes of material and are often used in commercial printing environments.

- Saddle Wire Stitching:

- Similar to saddle stitching, saddle wire stitching involves using stitching wire to bind folded sheets along the spine. This method is commonly employed for magazines, booklets, and catalogues.

- Stitching Wire Types:

- Stitching wire comes in various thicknesses and materials. Common types include round wire and flat wire. The choice of stitching wire depends on the thickness of the document being bound.

- Loop Stitching:

- Loop stitching involves creating a loop with the stitching wire, allowing the bound document to be hung or inserted into a ring binder. This is useful for presentations and promotional materials.

- Saddle Wire Stitching with Trimming:

- Some stitching machines include trimming units that trim excess wire and paper, providing a clean and finished look to the bound document.

- Wire Binding:

- Wire binding involves using a wire binding machine to punch holes along the edge of the sheets and then threading a wire through these holes. The wire is then closed to secure the pages, creating a more robust binding suitable for presentations and manuals.

Both staples and stitching wire are versatile options for print finishing, providing different levels of durability and aesthetic appeal. The choice between them depends on the type of document, the desired presentation, and the volume of production.