Encapsulating printed work involves sealing it within a protective layer of plastic film, typically using a laminating process. This process offers several benefits for preserving, enhancing, and protecting printed materials. Here are some advantages of encapsulating printed work:

- Durability:

- Encapsulation provides a durable protective layer that guards against wear and tear, ensuring the longevity of printed materials.

- Water Resistance:

- The plastic film used in encapsulation is waterproof, making the printed work resistant to water damage, spills, or environmental exposure.

- Stain Resistance:

- Encapsulation creates a stain-resistant surface, making it easier to wipe off fingerprints, smudges, or other marks without damaging the printed content.

- Enhanced Strength:

- The plastic film adds strength and rigidity to the printed material, reducing the risk of creases, bends, or tears.

- UV Protection:

- Encapsulation provides a layer of UV protection, preventing the printed content from fading or yellowing due to exposure to sunlight or artificial light.

- Easy Cleaning:

- The smooth, sealed surface of encapsulated materials is easy to clean with a damp cloth, maintaining a fresh and professional appearance.

- Improved Appearance:

- Encapsulation enhances the visual appeal of printed work by adding a glossy or matte finish, depending on the type of plastic film used.

- Professional Presentation:

- Encapsulated materials have a polished and professional appearance, suitable for presentations, displays, or any printed items intended for long-term use.

- Increased Thickness and Rigidity:

- The encapsulation process adds thickness and rigidity to the printed work, giving it a substantial and high-quality feel.

- Writable Surface:

- Some encapsulated materials allow for writing with dry-erase markers, making them suitable for reusable charts, posters, or other instructional materials.

- Tear Resistance:

- The encapsulation process reinforces the material, making it more resistant to tearing and ensuring that the content remains intact.

- Preservation of Information:

- Encapsulation protects important information, such as maps, charts, or reference materials, by preventing damage from handling, folding, or exposure to the elements.

- Customization Options:

- Different types of plastic films and finishes provide customization options, allowing you to choose the level of gloss, matte, or texture that suits your design preferences.

- Versatility:

- Encapsulation can be applied to a wide range of printed materials, including posters, maps, instructional guides, menus, and more.

- Easy Reprint or Replacement:

- If the encapsulated material needs updating or replacement, the encapsulation can be cut open, and a new print can be inserted without damaging the underlying layer.

Encapsulation is a versatile finishing option that offers protection, longevity, and a professional appearance for various printed materials. Whether used for educational charts, marketing collateral, or frequently handled documents, encapsulation provides a reliable solution for preserving and enhancing printed work.

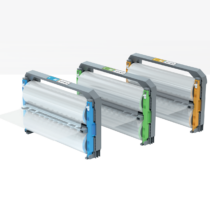

Encapsulation Films

Encapsulation Films